Seminars & Events

View More

DX Solutions

IPS DX Approach

We are not an AI/IOT store. Say goodbye to individual optimization and POC fallout. Let’s aim together to create concrete management effects, total optimization of companies and factories, and new value creation!

DX is used in a variety of ways, from the creation of new value through the use of digital technology to the mere use of IT. We are particularly concerned about the fact that there are many cases where individual operations have been improved by using AI, and that the specific implementation has not progressed beyond POC, and has not led to significant management effects. We are differentiated from such cases and provide consulting services from two perspectives in order to support customers who have implemented ERP to aim for further transformation.

Perspective 1

We aim to deliver direct, measurable management benefits across the enterprise or entire factory using new technologies—working closely with our clients to achieve this. For example, by reviewing not only ERP-covered processes but also peripheral operations and applying IT, we help dramatically boost efficiency and reshape workforce structures. We also support productivity gains across entire factories by applying cutting-edge technologies such as AI and IoT.

Perspective 2

Our goal is to solve client problems. To do this, we identify and engineer the optimal technologies and solutions from a vast ocean of information. Many IT vendors simply sell individual technologies or solutions like AI, IoT, or RPA—but they do not address the root problems businesses face. Today’s technologies are highly advanced yet fragmented and specialized, and many companies are unaware of the solutions that could address their challenges. That’s why our clients need engineering.

Smart Factory Solutions

One of our key focus areas in DX is Smart Factory Support Services. Drawing on extensive SAP implementation experience in manufacturing, and a deep understanding of production management and holistic optimization, we help clients rethink factory operations and management to boost output and reduce costs. While “smart factories” often conjure images of expensive automation equipment, robots, or AGVs, our concept focuses on leveraging , using IT to eliminate bottlenecks and maximize productivity. We welcome the opportunity to explore what kinds of improvements and reforms are possible at your factory.

Let’s start with planning your digital transformation vision.

Case

Case 1

We monitor the cooling state—a key factor in quality control—for film inflation molding using infrared cameras to detect abnormalities and trigger alarms. The goal isn’t just automation or efficiency, but building unwavering confidence in the quality of products delivered to clients. The future aim is to control processes based on detected cooling conditions.

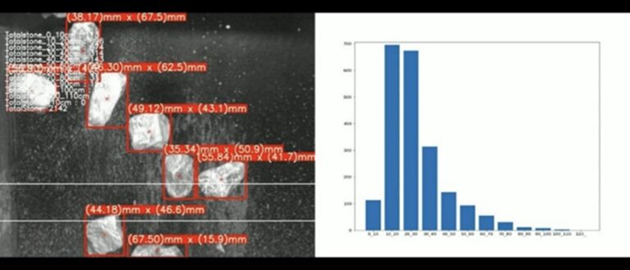

Case 2

We measure the size of limestone before it's fed into the calcining kiln—this is the first step to optimize firing and improve yield in lime production. Knowing stone size allows operators to estimate the appropriate fuel and airflow. The long-term goal is to automate and optimize this process.

Case 1

applied specialized infrared cameras (not AI).

Case 2

used machine learning based on video + object detection models.

We continuously collect insights, conduct technical research and testing, and pursue optimal solutions tailored to each client’s challenges.

This is where our engineering services truly shine.

Networking & Alliances

To solve our clients’ challenges, we’ve built a strong collaboration network to bring in a broad range of expert knowledge and advanced technologies.

Technical Advisor

Dr. Hajime Nagahara

Professor

Intelligent Information Infrastructure Laboratory

D3 Center

Osaka University

Industry Associations

Smart Factory Research Group

Japan Institute of Engineering

Factory Scientist Association

– Supporting Member

Considering DX Support Services?

We’re Here to Help

For those considering SAP solutions

For those considering SAP solutions

Certified Partner Program

Certified Partner Program